Our motivation

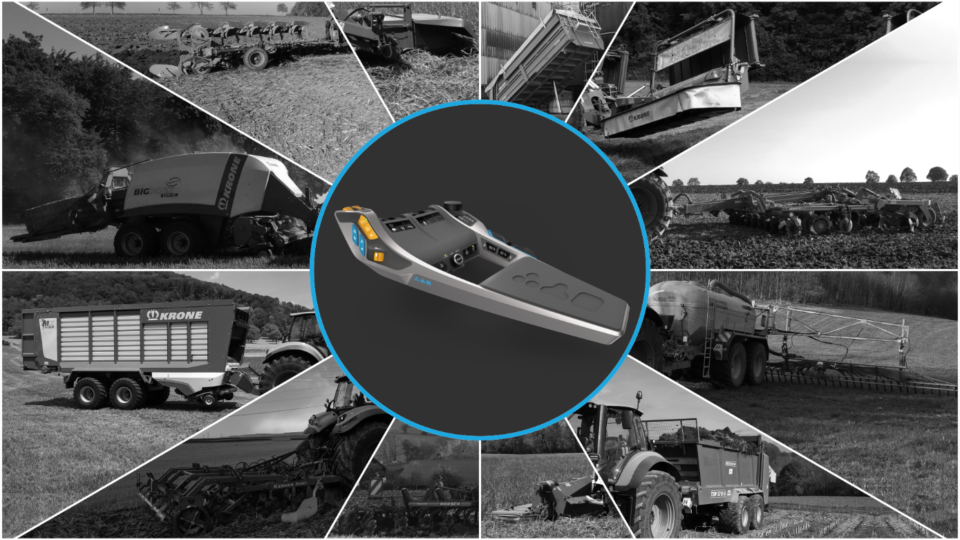

Considered to be a universal machine, the tractor is primarily used in agriculture, and also forestry, construction and the municipal sector. It has gained its reputation as a universal work machine from its interface equipment for pulling, driving and picking up attachments and implements.

As there is such a wide variety of work equipment available, each interface is capable of being used differently to suit each application. In particular, the hydraulic and PTO interfaces serve a wide functional range. However, current tractor operating systems do not accurately replicate this functionality either in an expectation or movement compatible manner. Not being functionally accurate results in the PTO always being engaged or disengaged, rather than the baler or mower being engaged or disengaged. Or, that instead of tilting the tipping bucket or the pickup up or down, the extension and retraction of a hydraulic cylinder is always operated. Consequently, and particularly in hydraulics, the assignment of control valve operating elements to functions on the attachment is not always obvious. DIN EN ISO 9241-110 Principles of dialogue design says about task adequacy:

An interactive system is task-appropriate if it supports the user in completing his or her work task, i.e. if functionality and dialogue are based on the characteristic properties of the work task rather than on the technology used to complete the task.

Not being in line with user expectations means, a constant hydraulic flow, such as the blower fan of a pneumatic seed drill, is switched on or off with a flat tilt lever instead of a button. Movement incompatibility is where a user moves the support leg of a trailer upwards by moving the associated control element, for example, a proportional flat tilt lever downwards, and vice versa. DIN EN 894-1 Safety of Machinery says about expectation conformity:

Population stereotypes and other user expectations about how the human-machine interface works strongly influence the user in the way he or she uses a particular actuator or display. Users are expected to fall back into population stereotypes in stressful situations, even if they would have to act in the opposite way according to their training.

Movement compatibility is within the scope of this definition, as it is an intuitively expected that a control element will move in the same direction as the functional element.

NEW FEATURES FOR NEW WAYS OF OPERATING TRACTORS

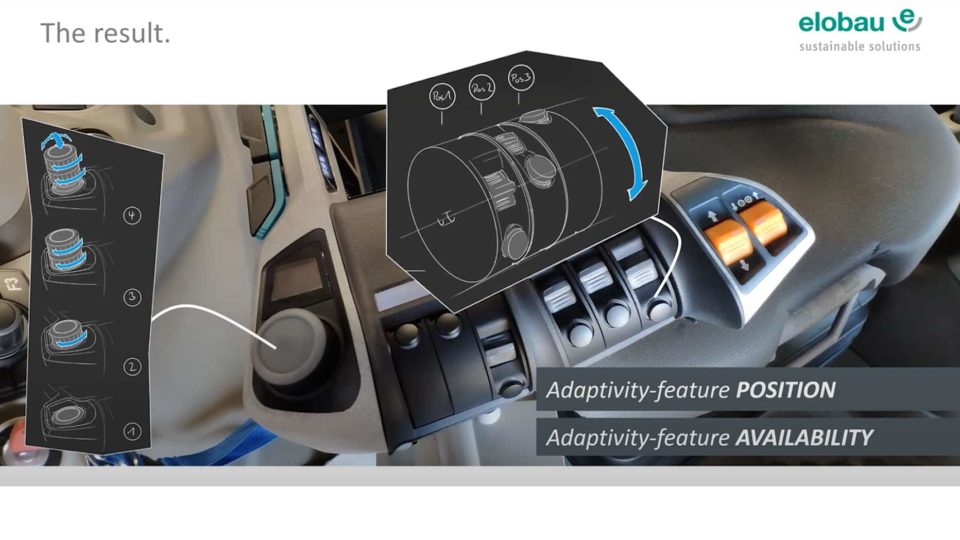

Regarding the weak points of current tractor operating systems outlined above, the prototype adaptive operating armrest sets new standards. It features adaptivity in graphics, position, accessibility, and operating mode selector.

- Each adaptive control element is assigned a function symbol that clearly corresponds to the controlled function of the attachment. This provides clear identification of which control element is assigned to which function of the attachment. Further advantage: The function is always operated and no longer only the technology used.

- The actuation direction of each operating element can be adapted to an up/down or a forward/backward function to meet expectation requirements and motion compatibility.

- Controls are “hidden” when not in use to optimise clarity and ease of operation. A joystick is either completely hidden or only visible as one rotating wheel, two stacked rotating wheels or with its two joystick axles and rotating wheels. Controls for hydraulic functions are only accessible if they are assigned to a function.

- The operating mode selector switch automatically activates only the functions required for a particular attachment. Switching from road mode to work mode and vice versa requires the operation of a bundle of functions. The exact functions are specific to each purpose of use: Locking/unlocking the hydraulics and/or the linkage, activating/deactivating the traction management and/or the steering system as well as hydraulically folding in/out an attachment. The mode selector switch enables these functions to be accessed and controlled as a group, and always only what is relevant to the current operating scenario.

- The operating area has been ergonomically designed to increase clarity and ease of use for the operator, especially for frequently used functions.

Webinar - This is aISA

For further information please contact:

Timo Schempp

t.schempp@elobau.de

+49 (0) 7561 970-793

Comments

write a comment