The new vibration module made by elobau introduces a way for machine and vehicle manufacturers to engage with operators’ tactile sensory systems. The module is compatible with the Heavy duty joystick J4F and midi modular armrest 225MA. The module is integrated into the 361G/362G and 341G/342G multi-function handles.

Mobile machine operators are exposed to a lot of noise and visual impressions, all of which they have to filter out or process. Loud engine noises, flashing warning lights, displays and a hectic and dusty working environment take their toll and are stressful to both the acoustic and visual sensory systems. And all this while the machine operator tries to concentrate on their actual work. However, tactile perception, i.e. the sensitivity of the skin’s surface to touch and other sensations, is hardly addressed. It has great potential for optimising human-machine interaction thus increasing efficiency and safety in the operation of mobile machines.

The new vibration module from elobau takes advantage of this potential. High-quality tactile feedback can be generated using certain vibration patterns, making human-machine communication more efficient. The amount of information being transmitted can be significantly increased compared to simple, sporadic knocking signals. Vibration effects make operation more intuitive and reduce the time needed to master a machine. The risks of incorrect operation are also reduced. Improved operating comfort boosts endurance and concentration, which also contributes to safe operation.

There are many ways in which the vibration patterns can be used to communicate with the operator. For instance, cues or warnings given by the vibration module can help to accelerate response times. The support provided by haptic feedback guides the operator through their respective tasks. This improves both the efficiency and precision of their work.

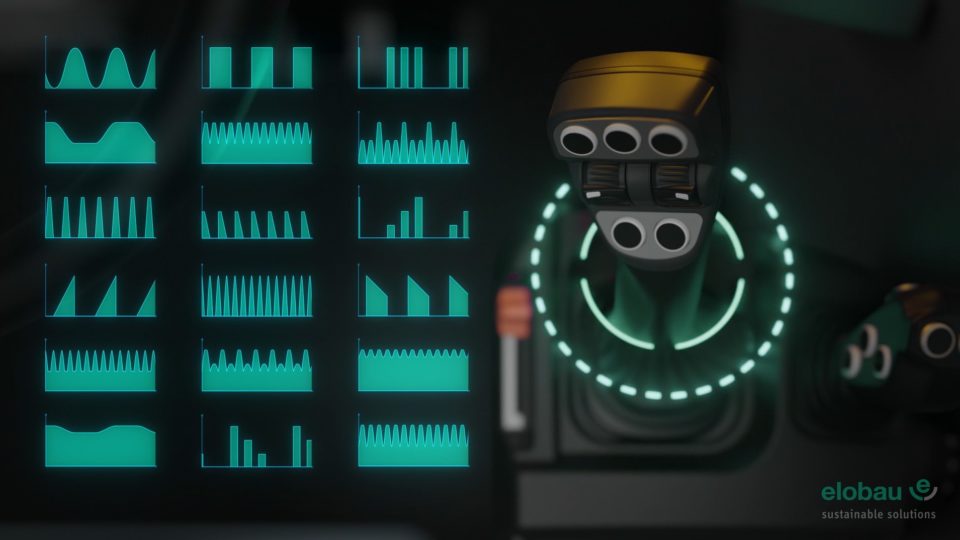

The vibration motor is controlled by an electronic module via the CAN-Bus and can generate a variety of vibration characteristics. Manufacturers can use the CAN protocol to define different parameters, such as intensity, duration or number of vibrations. These parameters generate distinctive vibration effects that are tailored to the application and, above all, can be intuitively understood.

Different vibration effects can indicate an overload situation or emergency shutdown. They can also be used to confirm that automatic workflows have been completed. Additionally, vibrations can indicate the proximity of nearby objects, the position of the user’s own machine or when the configured working range limits are approached. They can generate vibrations that decrease in length the closer the operator gets to a foreign object, in a similar manner to park distance control systems used in cars. This is a useful alternative to acoustic warning signals in the often noisy surroundings of many workplaces. Functions such as fatigue monitoring alarms or detection of nearby pipelines are conceivable.

The new elobau vibration module is an additional option in the range of human-machine communication equipment for manufacturers of mobile machines and systems. Vibration alarms and tactile feedback can be used in a variety of ways, opening up new opportunities for optimising safe and efficient workflows. The vibration module is now available.

Leutkirch, 14/02/2022

Words: 529

Characters with spaces: 3544