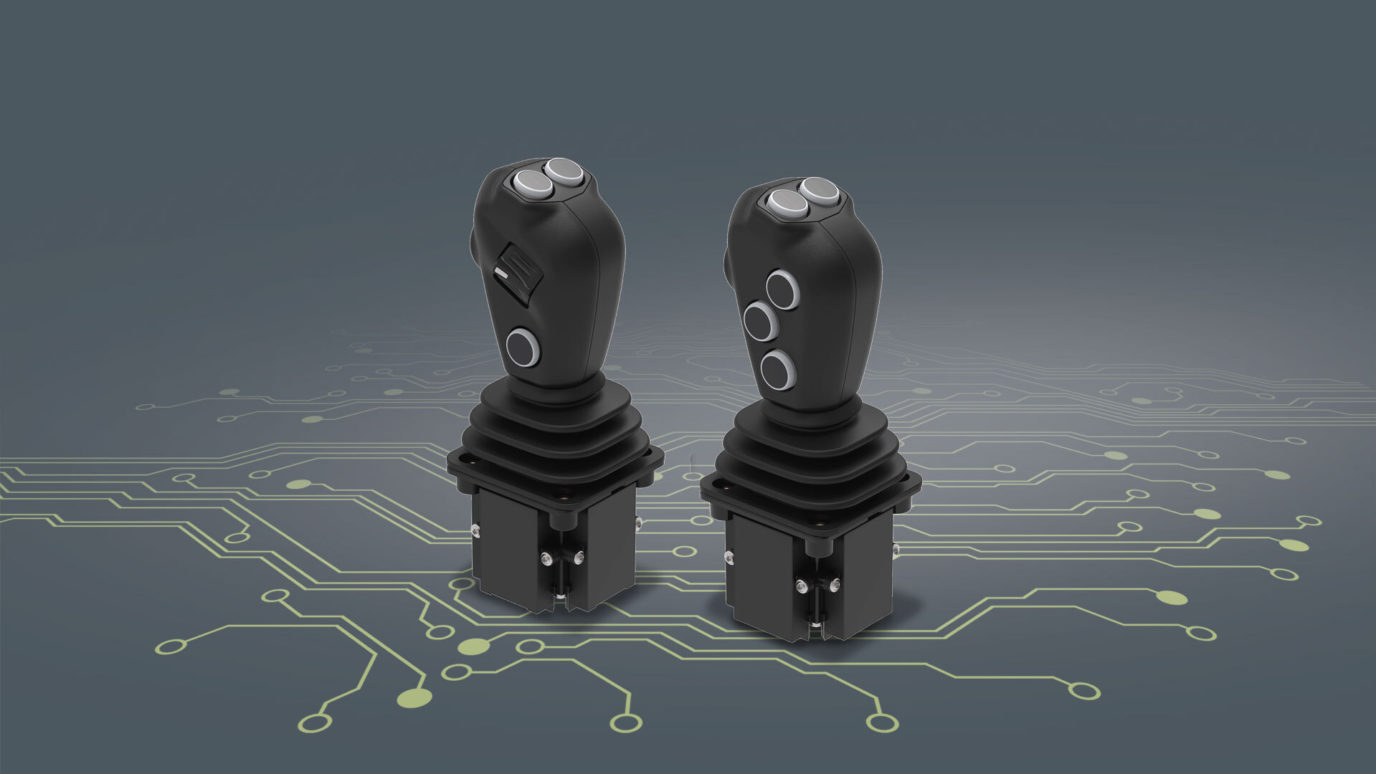

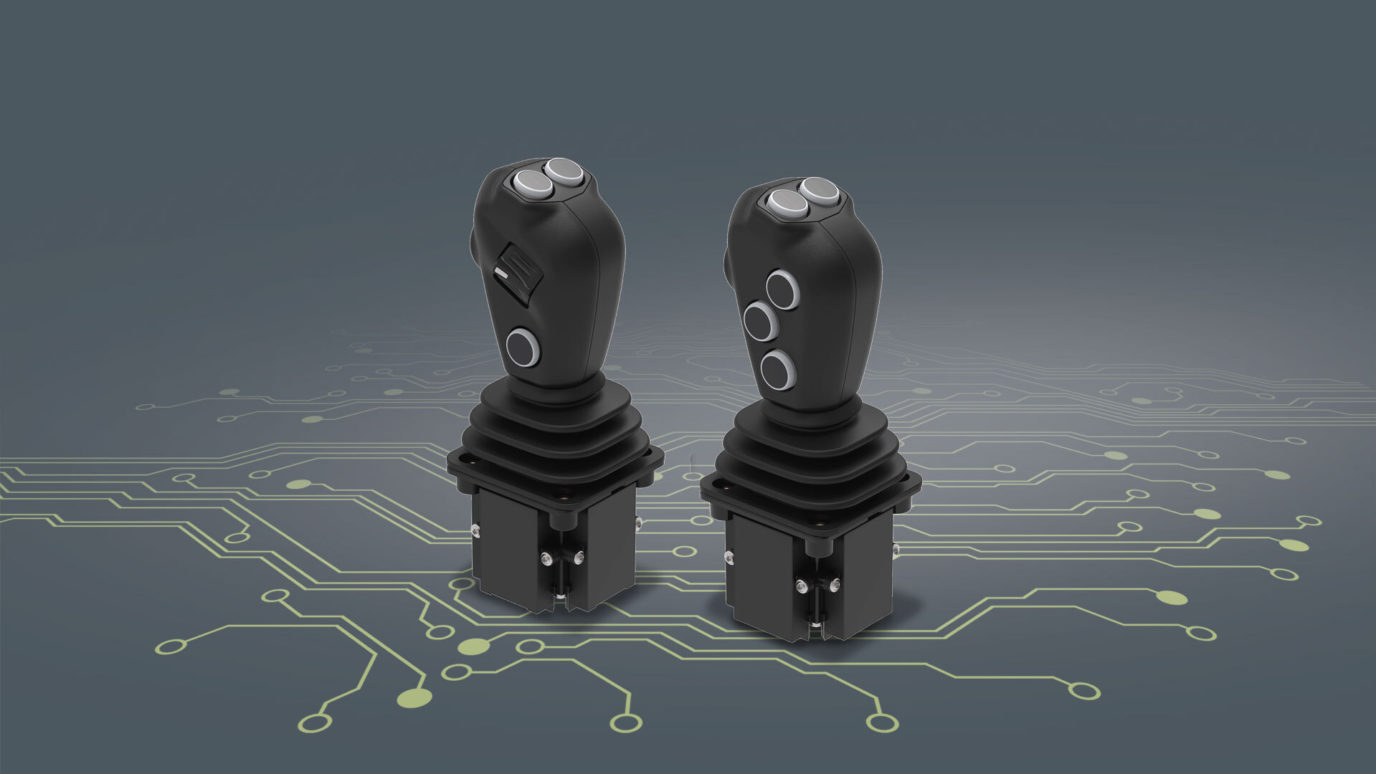

The joystick grip is particularly suited to the precise and safe operation of front loader and hydraulic functions. It provides manufacturers of agricultural, construction and special machines with a flexible and compact solution for the tried‑and‑tested J2 joystick base.

The 321G can be equipped with up to six push buttons or alternatively with up to four push buttons and a thumbwheel. The joystick grip therefore allows the operator to centrally control more functions on the machine than is usually possible. This saves the operator from having to continually alternate between the joystick and the control panel, for example. The ergonomic layout of the components means that the operator can access the functions more easily, and ensures fatigue‑free operation.

Freely configurable

All of the operator controls integrated in the grip can be freely configured and therefore provide the machine manufacturer with a high degree of flexibility. The output signals are transmitted either analogue or using the CAN bus protocol (J1939/CANopen).

321G: For applications that require dexterity

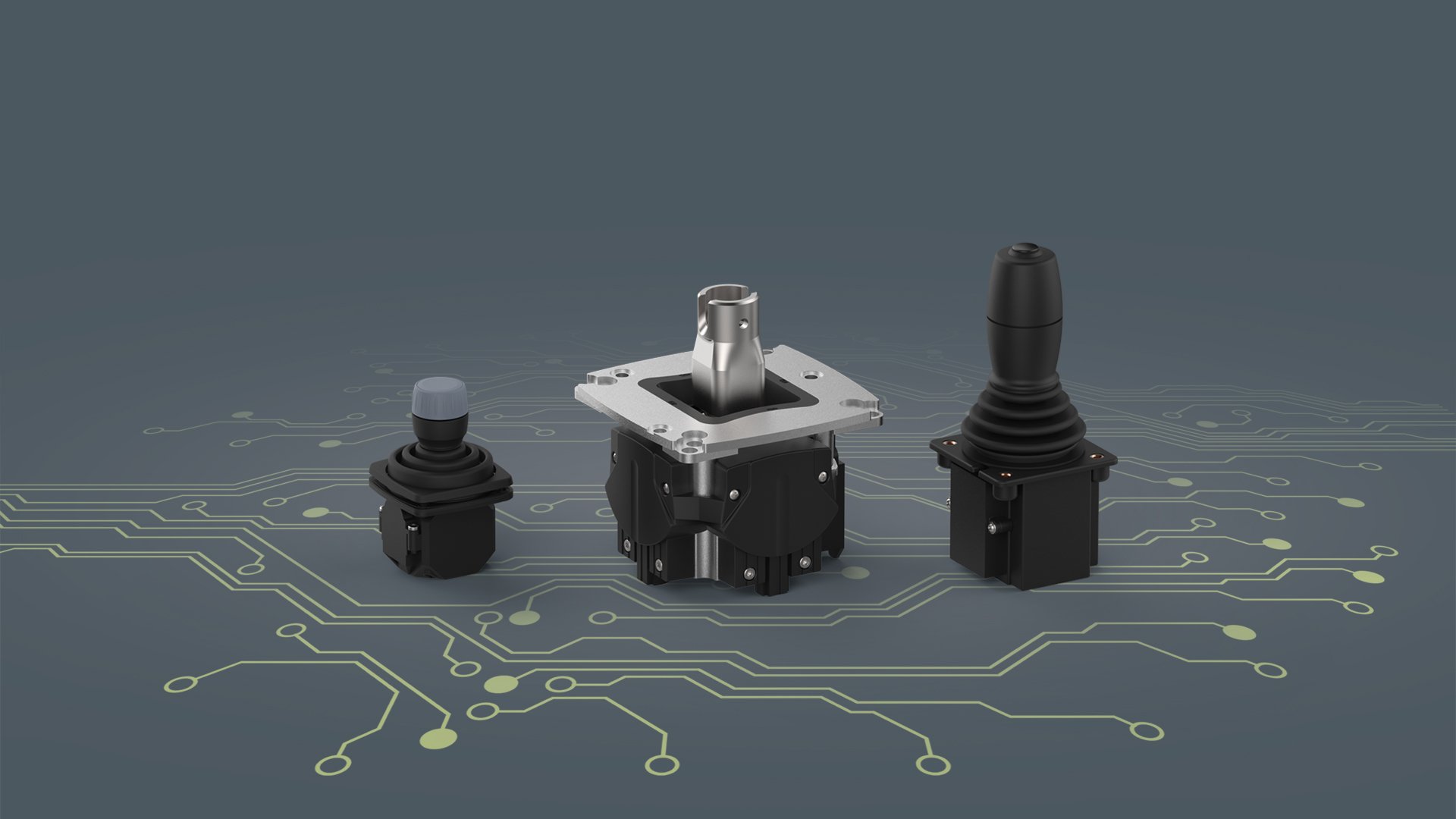

Measuring 43 x 90 x 55 mm, the joystick grip offers a high level of functionality in an extremely compact design compared to other products available on the market. Thanks to its responsive operation, it is particularly suited to applications where precise control is often required. For the float position of the hydraulics, the joystick has detent points at both the forward and right end positions in order to hold the 321G at the respective position. The joystick grip conforms to EU 167/2013 (Mother Regulation) and has protection class IP5K4.

The J2 compact joystick has already long been used successfully e.g. for controlling front loader functions on tractors. It is mounted to the armrest from underneath, is highly reliable, has a long service life and is available with various actuation types, e.g. no‑detent or detent actuation.

Comments

write a comment