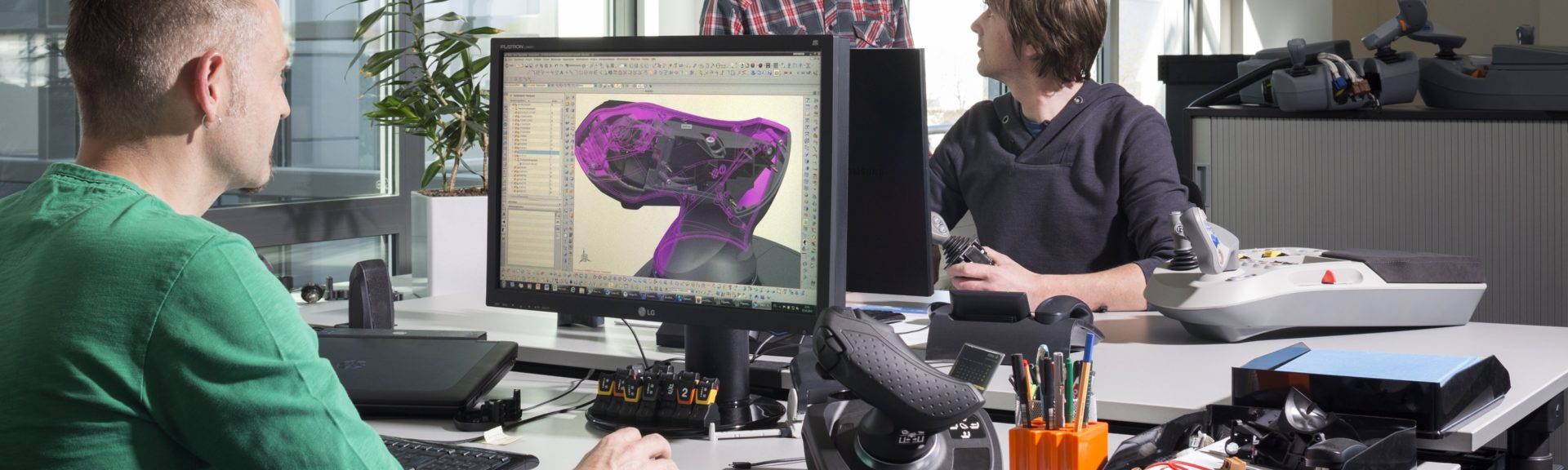

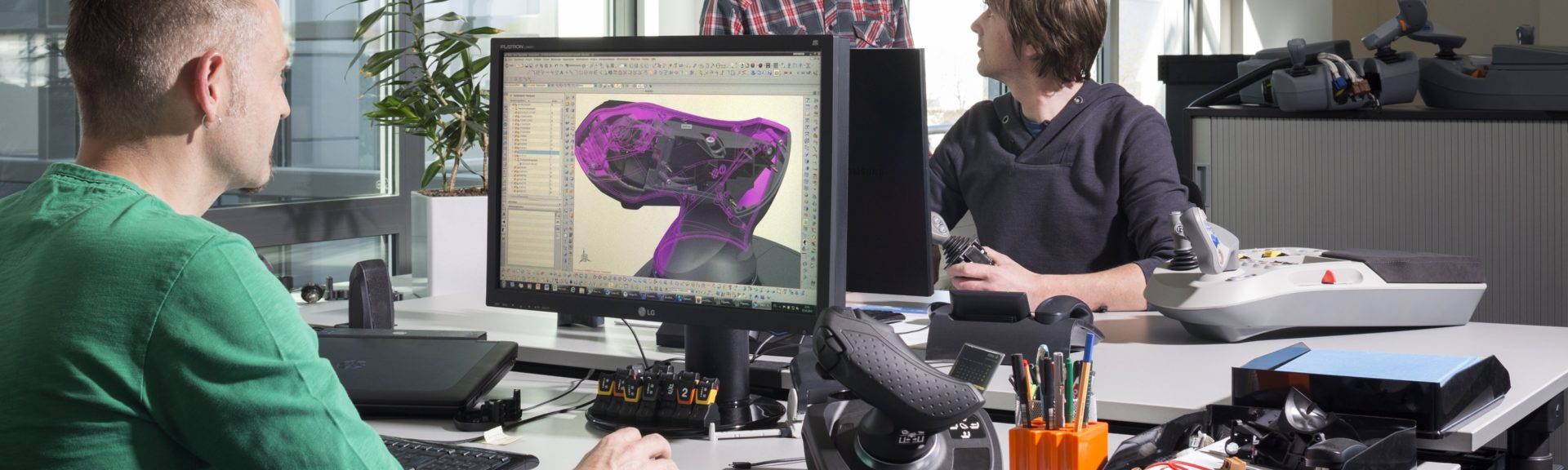

All development steps in-house

All important development processes, such as the mechanical design, electronic hardware and software design, PCB layout, and tool design are carried out in-house. Our prototype development and production rounds off our full range of offerings with the test laboratory for material testing including service life and/or climate tests. We develop and manufacture exclusive, customer-specific solutions tailored to the respective application. Almost all components feature contactless switching elements. As a result, they are affected by neither dust nor moisture and are consequently perfectly suited for use in adverse environmental conditions.

The course for how sustainable a product can be manufactured and whether the product can be adapted to changing requirements in the future is already set in the design phase and during the individual development stages. We consider aspects such as modifiability, modularity and reusability right from the start of product development. Simulations and tests allow us to check whether we have met the requirements before the first prototypes are even produced. With our modular standard armrest MA225, we have implemented the use of bio-based plastics for the first time. For customer-specific developments, a fixed project team works together from the design phase to series production. This means that the customer deals with the same contact persons throughout.

Product has been added to watchlist.

bauma 2025

00

Days

00

Hours

00

minutes

00

Seconds