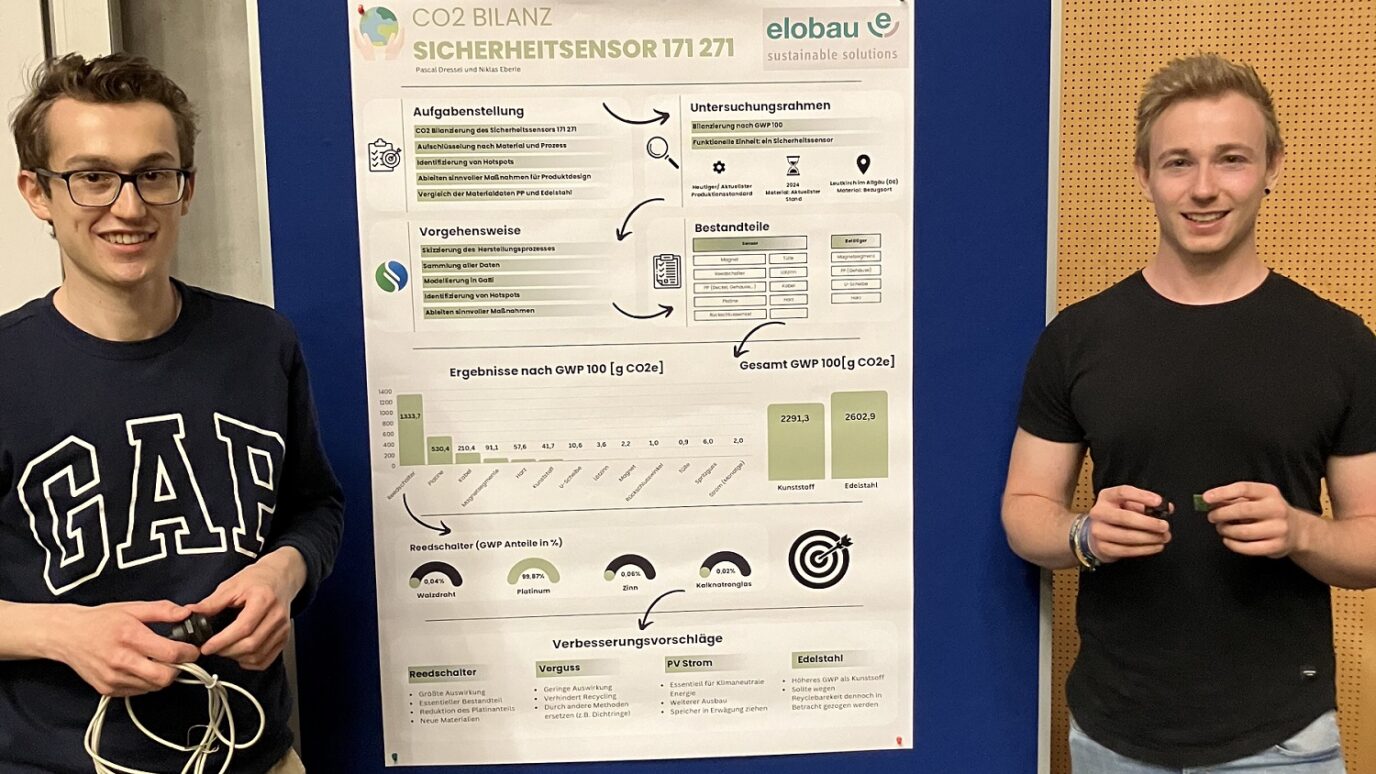

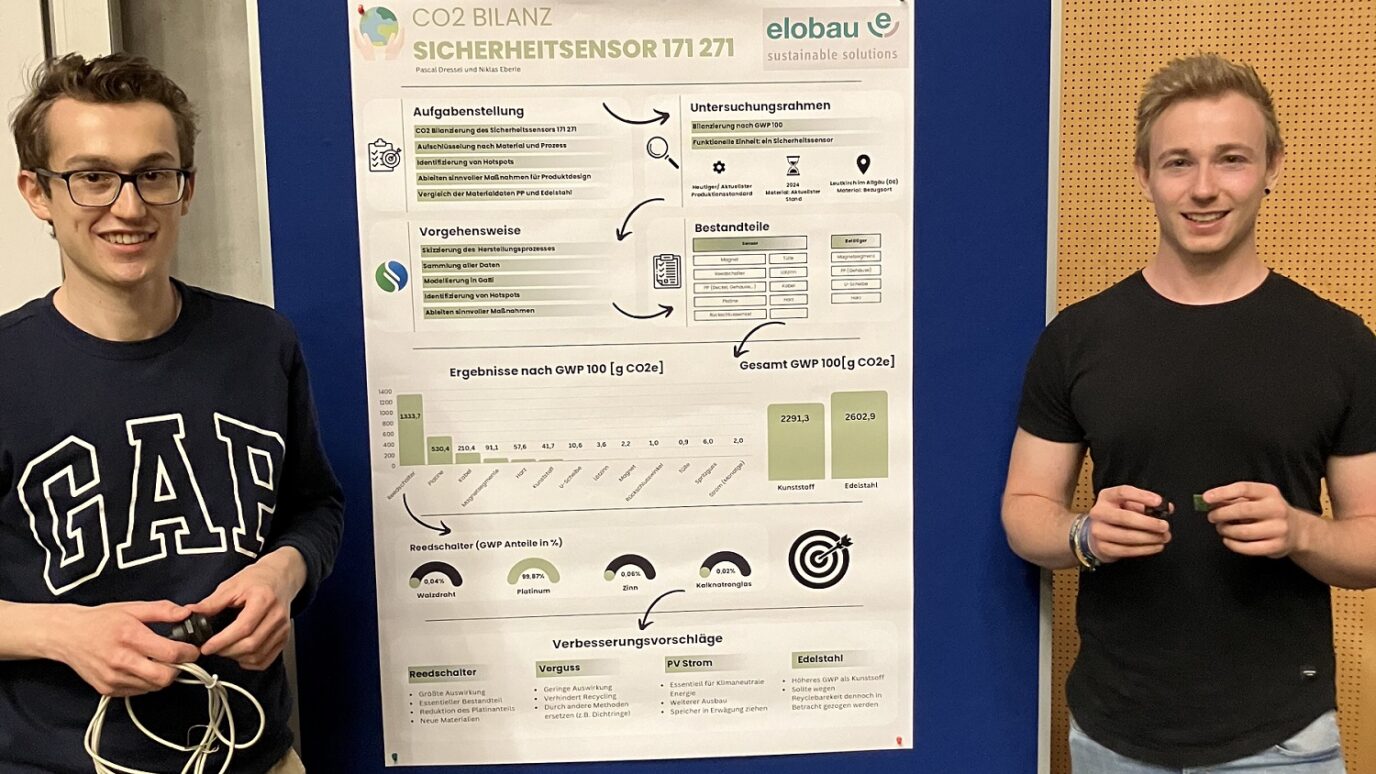

The project was carried out between February and August 2024 and focused on the ecological and CO2 balancing of technical products and systems. Specifically, it involved calculating the CO2 footprint of the 171271 safety sensor from elobau. The main objective of the research was to analyze the CO2 emissions of the plastic sensor, to identify the main emission points and to recommend and derive concrete measures to reduce the CO2 footprint for future designs.

Due to the interdisciplinary nature of the study, elobau’s Sustainability and Product Management Industry departments were involved. As part of the project, a tour of Plant 1 at elobau’s headquarters in Leutkirch took place in order to observe relevant processes on site and record data. In addition to elobau, other companies also took part in the study, including Bosch, Multivac, Fendt and Thöni.

The students presented the results of their study at the final event in the auditorium of Kempten University of Applied Sciences. These showed the improvements that can be made to reduce CO2 emissions and how this can increase the sustainability of the sensor.

The project once again highlighted the advantages that cooperation between companies and research institutes can bring for both sides: on the one hand, it provides students with practical career orientation, and on the other, contact with research offers companies the opportunity to develop new approaches to solutions through an outside perspective. This is why elobau is all the more pleased to continue its excellent partnership with Kempten University of Applied Sciences also next year as a practice partner.

Comments

write a comment