change!

Next Generation Tilt Sensors

Change now – and easily optimize your machines and processes

Here comes the new generation of tilt sensors N6 static and N7 dynamic – ideal for use in mobile machinery.

Elobau tilt sensors are state of the art, operate with high precision using powerful MEMS technology and offer decisive advantages – for users as well as for vehicle and machine manufacturers.

N6 static and N7 dynamic – developed for even greater safety, reliability, functionality and flexibility. Tilt measurement has never been easier – whether in static or dynamic applications.

Higher functionality, more safety and comfort for the operator

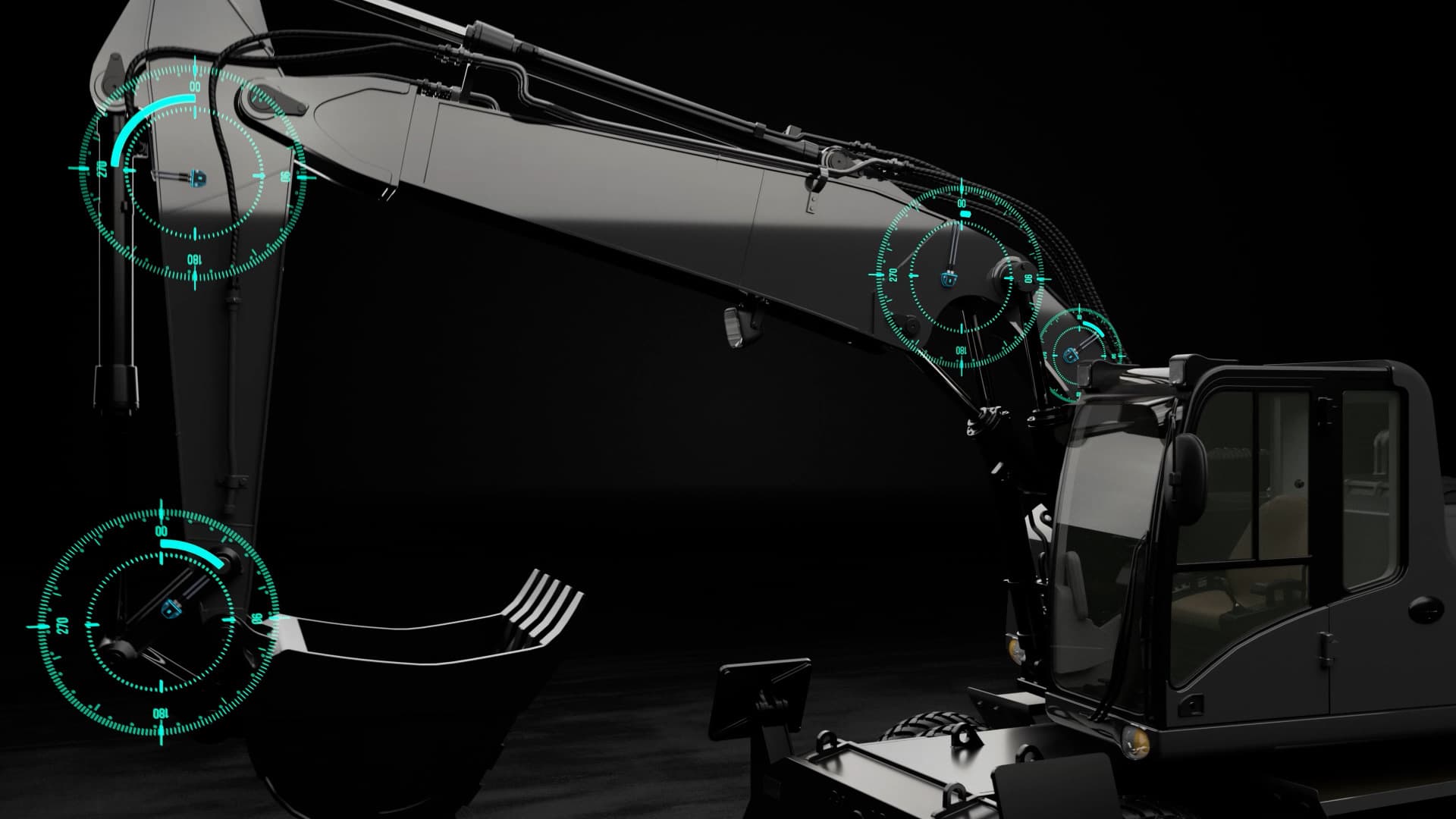

The sensors continuously monitor the angle of inclination of an object relative to gravity and thus reliably provide information for the safe control and movement of the mobile machinery. In this way, they enable important functions such as:

- Regulation of the cockpit level, automatic compensation of slope inclinations

- Position and tilt measurement of moving vehicle/machine parts, such as the boom of an excavator

- Stabilization/tilt protection by monitoring vehicle inclination

Material handling machinery

Agricultural machinery

Construction machinery

Take action now

make the world safer and more sustainable

Easy to choose – the perfect tilt sensor for your application

The N6 static achieves high precision in static systems or with slow machine movement → MEMS technology

The N7 dynamic gives a precise measurement signal on mobile machinery despite shocking movements, bumps and vibrations → MEMS technology + Sensor Fusion (Kalman filter)

MEMS technology: robust and compact – for high precision

N6 static and N7 dynamic use MEMS (microelectromechanical systems) – small components that combine electrical and mechanical components on one chip. Any movement or position deviation is reliably registered and leads to a change in the output signal, which precisely indicates the current angle of inclination.

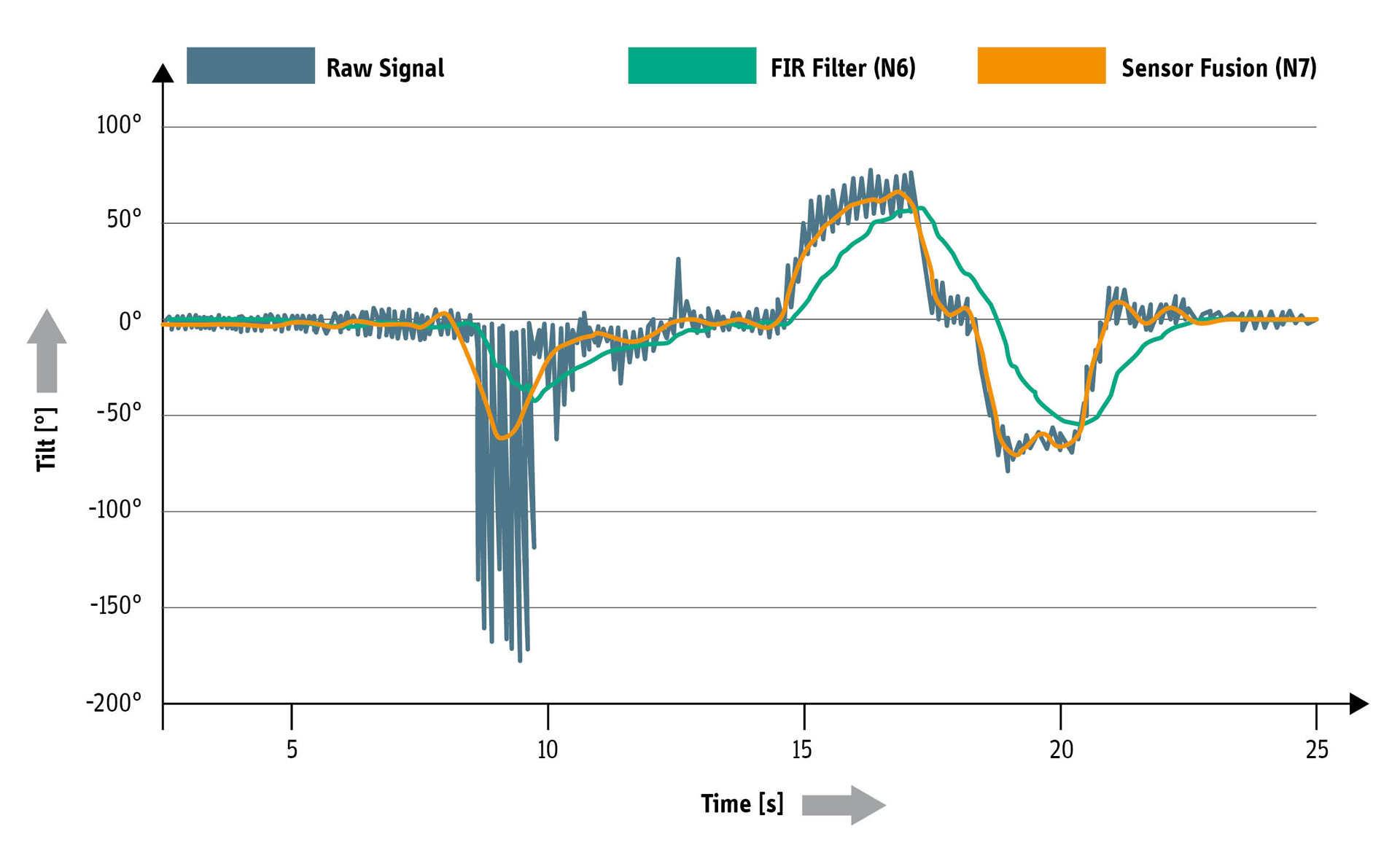

Sensor Fusion: clear signals even with strong shocks and vibrations

In case of particularly strong accelerations and jerky movements, purely gravity-based sensors reach their limits. For such dynamic applications, we have therefore equipped the N7 dynamic with Sensor Fusion – an extremely responsive combination of accelerometer and gyroscope.

To calculate correct tilt information, the measurements of both components are merged, any errors are corrected and filtered. The Kalman filter used for this is an algorithm that is based on relevant measurement and experience values, which compensates inaccuracies and thus optimizes the measured value stability of the N7 dynamic.

A tilt sensor with Sensor Fusion / Gyroscope significantly reduces the negative effects of jerky movements and ensures the provision of precise measurement data.

As precise as necessary, as cost-efficient as possible

The new tilt sensor generation stands for precision and cost-effectiveness made to measure. Therefore not every application requires the use of the N7 dynamic equipped with Sensor Fusion. For static or slow-moving systems, the more cost-effective N6 static is the perfect solution – and offers reliable tilt measurement at reduced costs.

High flexibility due to three different connector variants

N6/N7 with Deutsch DT04-08PA

N6/N7 with 1x M12 5-pol (male)

N6/N7 with 2x M12 5-pol (male/female)

N6 static and N7 dynamic – benefit from the advantages

- Precise and continuous measurement of the inclination of mobile machines

- Robust design for long service life: IP67 / IP69K protection class (ISO 20653)

- For different requirements, various connector variants can be adapted:

Deutsch DT04-08PA / 1x M12 5-pin (male) / 2x M12 5-pin (male/female) - Easy variant management due to smart modular system

- Thanks to efficient 2-point-mounting, installation is up to 30 % faster than with existing tilt sensors

- Familiar elobau sustainability through CO2-neutral production

Differences between the N7 dynamic and the N6 static

- N7 dynamic equipped with gyroscope and Sensor Fusion

- Possible output signals N7 – CANopen, SAE J1939

- Possible output signals N6 – 4-20mA, 0.5-4.5V, switching output, CANopen, SAE J1939

- Access to raw data from accelerometer and gyroscope opens up additional applications

Take action now

make the world safer and more sustainable